Top Benefits of Dynamic Balancing in Preventive Maintenance for Rotating Equipment

Preventive maintenance keeps rotating assets running safely and efficiently, yet balancing often gets overlooked until the vibration becomes obvious. Dynamic balancing corrects mass distribution while machinery spins, stopping harmful oscillations before they escalate. Here are five clear advantages that justify making balancing a part of regular maintenance: reduction of vibration, energy savings, smooth operation, earlier detection of failure modes, and enhancement of inspection intervals. Each of the benefits will support uptime, reduce lifecycle cost, and protect personnel. The following will give a concise explanation of how balancing transforms routine care into strategic reliability management.

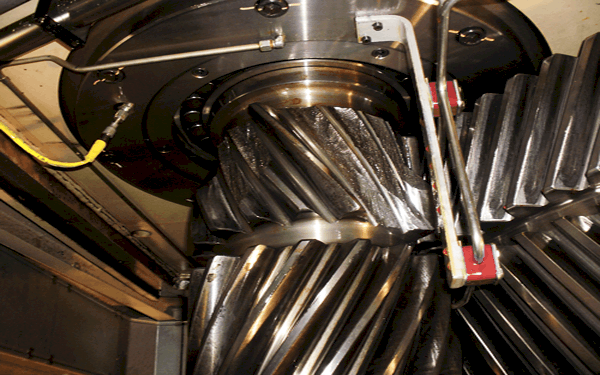

Lower Vibration, Longer Component Life

Bearings, shafts, seals, and couplings are subjected to high levels of vibration that cause excessive stresses which lead to quicker wear and tear; dynamically balancing rotors balances centrifugal forces, greatly reducing the oscillatory loads transmitted to support systems and therefore reducing the rate at which rolling elements and containment seals degrade, reducing the number of corrective repairs and the size of spare parts inventories. The reduction of vibration also reduces the chances of fatigue cracking at points where there are increased stresses on structural components, thereby providing structural components with increased strength through additional service cycles. For project managers and plant engineers, this means that planned equipment maintenance will be more predictable and that equipment performance will be more stable.

Reduced Energy Consumption and Operating Cost

Unbalanced rotors require more torque to sustain speed because motors have to work against uneven loading. Corrective balancing reduces resistive forces, allowing drive units to approach their nominal efficiency ratings. Reduced electrical draw cuts utility bills, and motors suffer less thermal stress to minimize insulation breakdowns and prolong service life. Multiplied across several machines, the incremental savings provide a justification for investment in equipment. Furthermore, quieter operation often correlates with improved workplace conditions, cutting indirect costs related to absenteeism and morale.

Early Detection of Premature Failure

Balancing programs are often coupled with vibration analysis, which reveals subtle symptoms before catastrophic failure. Trending imbalance signatures, bearing defect frequencies, or coupling misalignment indicators allow technicians to determine root causes rather than chase symptoms. To capitalize on that insight, plant teams should invest in dependable dynamic balancing services that connect measurement to corrective action. A single balancing session might indicate the presence of loosened mounting fasteners, deposits entrapped on impellers, or material loss at welds, all conditions inviting targeted interventions that avoid unplanned stoppages.

Smoother Operation and Process Quality

Any time there are processes utilizing spinning motion, such as machining or pumping, vibration will limit the amount of precision available for those processes. Having a balanced rotating part will create stability for that rotation, which in turn will allow for tighter tolerances, a consistent flow rate, and fewer scrap parts. The operators will see better control of the equipment, and feedback from sensors to the automated controls will be cleaner, resulting in better regulation of closed-loop control systems. Reduction of mechanical chatter will also provide less opportunity for secondary damage to the auxiliary systems, thus allowing the respective equipment to benefit from increased reliability and quality of output.

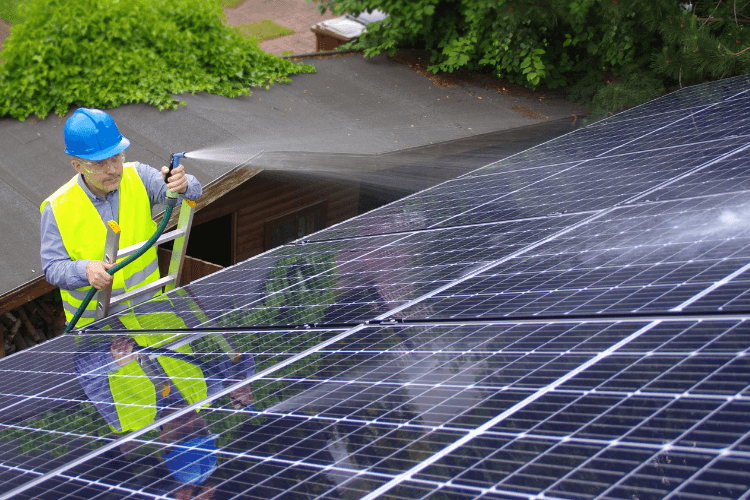

Longer Inspection Intervals and Lower Downtime

When the machines operate with reduced imbalance, deterioration rates slow, and therefore inspection regimes can be stretched safely. Condition-based scheduling becomes practical: The teams plan access, spare allocation, and skilled labor around predictable windows rather than reacting to alarms. Fewer emergent shutdowns free maintenance crews for value-added tasks such as root-cause projects and system optimization. That improves throughput from an operational standpoint, reduces the frequency of expensive overtime repairs, yet preserves capital budgets for strategic upgrades.

Dynamic balancing is not a one-off fix but a proactive measure that multiplies across asset classes. All it takes to bring in engineering discipline is the implementation of a program: baseline measurement, corrective runs, documentation, and periodic verification. These steps create an audit trail that will support continuous improvement and risk reduction. In addition, training maintenance personnel to recognize symptoms of imbalance embeds reliability on daily rounds and raises the overall maturity of plant maintenance.

Dynamic balancing rewards organizations with real improvements in reliability and financial returns. Reduced vibration prolongs component life; energy efficiency trims operating expense, stabilized rotation boosts process quality, early detection stops premature failures, and longer service intervals lower downtime. By treating balancing as a core preventive task rather than an emergency repair, teams turn reactive fixes into planned improvements that make assets more predictable and costs more controllable.