5 Reasons Predictive Maintenance Strengthens Industrial Systems

Running an industrial operation comes with constant pressure to keep things running smoothly. Machines that break down unexpectedly can cause major delays, waste resources, and even put safety at risk. When a single piece of equipment fails, it can slow down an entire production line and affect delivery schedules. To avoid these costly interruptions, many industries are now turning to predictive maintenance. Instead of waiting for something to break, predictive maintenance uses data and technology to detect problems early. This approach not only keeps systems working efficiently but also saves time and money in the long run.

Improved Equipment Reliability and Heavy Duty Ball Transfer Unit Performance

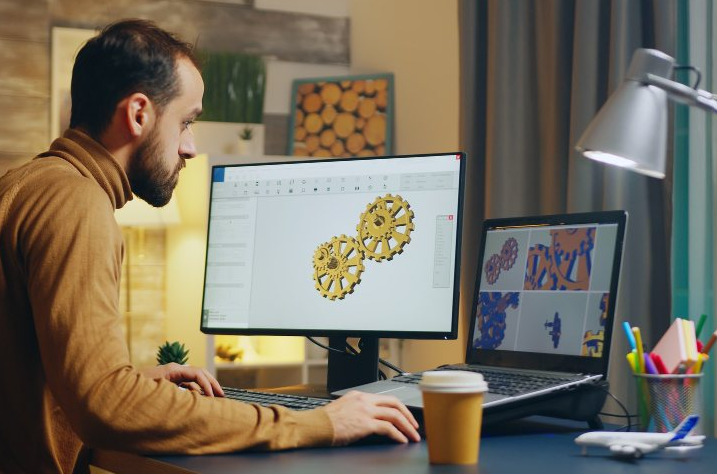

One of the biggest strengths of predictive maintenance is its ability to improve equipment reliability. In large industrial setups where precision is everything, even small faults can cause major disruptions. Using predictive methods allows you to monitor your machines continuously and identify issues before they turn into breakdowns.

This becomes especially important when handling parts that require smooth movement, such as a heavy duty ball transfer unit. Predictive maintenance ensures that equipment like this continues to perform at its best, reducing friction, wear, and costly replacements.

See also: Top 20 FoodTech Software Development Companies in 2025

Reduced Downtime and Production Losses

Unexpected downtime is one of the biggest challenges in industrial operations. When a key machine stops working without warning, production comes to a halt. Predictive maintenance helps you avoid this situation by alerting you when equipment shows signs of potential failure.

You can then plan maintenance during off-hours or scheduled shutdowns, ensuring minimal impact on productivity. By preventing surprise breakdowns, predictive maintenance gives you more control over your production schedule. This allows teams to stay focused on meeting deadlines rather than fixing emergencies.

Lower Maintenance Costs and Fewer Repairs

Traditional maintenance methods often rely on routine checks or waiting until something breaks. Both can be expensive. Routine checks can waste resources when done too often, while breakdown repairs can cost even more due to emergency parts and labor. Predictive maintenance finds the balance between the two. It allows you to fix what actually needs attention, nothing more, nothing less.

Over time, this reduces unnecessary repairs and lowers your maintenance budget. Since you’re fixing problems early, you also extend the lifespan of your equipment, which means fewer replacements and better long-term savings.

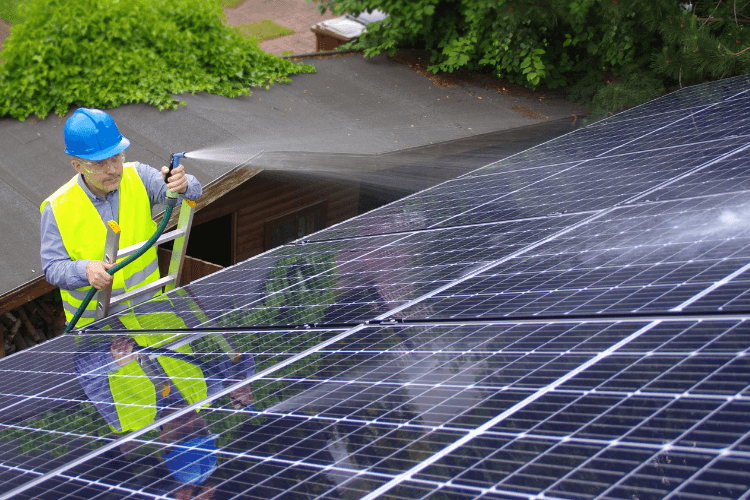

Enhanced Safety for Workers and Equipment

Safety is one area where predictive maintenance truly stands out. Malfunctioning machinery can be dangerous, leading to accidents or injuries. When you can detect and address faults early, you reduce those risks significantly. Predictive maintenance systems can monitor temperature, vibration, and pressure changes, factors that often indicate mechanical stress or failure.

By acting on this data, you keep both workers and equipment safe. This proactive approach creates a safer workplace where employees can focus on their tasks with confidence, knowing that the machines they rely on are functioning properly.

Better Planning and Resource Allocation

Predictive maintenance also helps you manage time and resources more effectively. When you know which machines will need attention and when, you can plan maintenance schedules more efficiently. This allows your team to order parts in advance, assign the right technicians, and minimize production disruption.

Over time, this type of planning improves workflow and reduces wasted effort. Instead of reacting to emergencies, your maintenance team can focus on keeping systems strong and stable, which helps the entire operation run more efficiently.